Top 20 Reasons Fabricators Choose the Advantage Laminating System

1. Easy To Handle, 100% Adhesive

HMT's Advantage hot melt adhesive film is similar to the material used in glue guns but cast in the form of a thin, flexible fabric. It's easy to handle — it can be held in your hand and won't stick to you despite the fact that it is 100% adhesive. "100% adhesive" means there is no liner paper to be peeled off before use.

2. Glue Virtually Anything

Bond combinations of materials including particleboard, high pressure laminate, wood veneers, linoleum, leather, paper, vinyl, cork, felt, aluminum foil, textured wall covering, carpet, screen, fabric, metal, hook-and-loop, plastic, sponge, foam, aluminum, rubber, insulation, natural products, and much more.

3. Zero Cure Time

HMT's Advantage hot melt adhesive films are quick setting. In fact, curing is 80% complete within seconds. Bonded materials can be used immediately. Instead of waiting hours or days for adhesive to cure, laminated output can be cut, drilled, or otherwise finished right away.

4. Faster Fabrication

When you bond laminates and substrates using traditional glue methods, you expose your organization to slow cure times, uneven adhesive application, toxic fumes, and time-consuming, messy cleanup chores. But you can eliminate these headaches and achieve faster fabrication by using HMT's Advantage Laminating System.

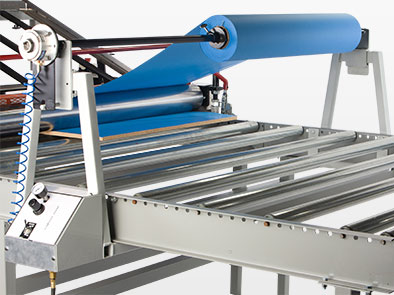

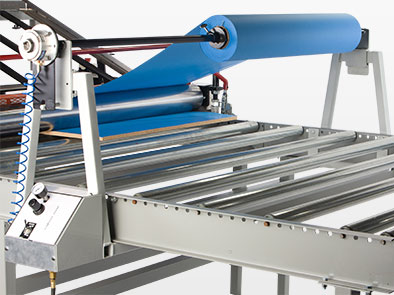

HMT's Advantage Laminating System includes our Advantage hot melt adhesive film and Advantage Laminator equipment. Replacing hot melt glue with hot melt adhesive film gives you:

HMT's Advantage Laminating System includes our Advantage hot melt adhesive film and Advantage Laminator equipment. Replacing hot melt glue with hot melt adhesive film gives you:

- output ready for immediate fabrication (no cure time, no waiting)

- even adhesive application

- solvent-free, toxin-free adhesive

- wipe-down cleaning (no need to fight messy glue in your shop)

5. Reduce Labor Costs

Reduced labor cost = higher profit and faster fabrication. But how does a fabricator reduce labor cost without sacrificing quality or laying off friends in the shop?

Answer: automation and advanced materials. HMT's Advantage laminator equipment applies consistent hot melt adhesive on a semi-automatic basis. Compared to manual, liquid hot melt glues, HMT adhesives reduce labor costs by up to 50% while offering 10 times more output.

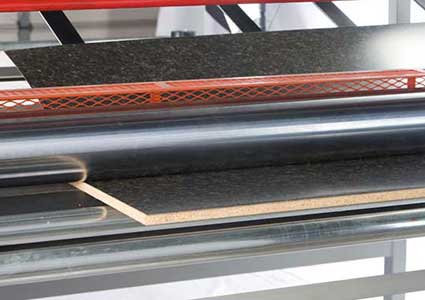

Laminates and substrates are fed into one side of the laminator. Finished laminated material comes out the other side, ready for immediate fabrication.

With Advantage hot melt film adhesive, there is no drying time. Because the adhesive is applied and adhered mechanically, there is no risk of uneven adhesive application caused by human error. Your labor costs will be reduced because you will produce more laminated output, faster, more consistently. You will eliminate waiting for panels to dry, and you won't spend time replacing panels that failed your quality inspection.

By producing more laminated output, faster, and more consistently, you can keep your team busy by accepting more jobs and letting them work on other projects around the shop.

Answer: automation and advanced materials. HMT's Advantage laminator equipment applies consistent hot melt adhesive on a semi-automatic basis. Compared to manual, liquid hot melt glues, HMT adhesives reduce labor costs by up to 50% while offering 10 times more output.

Laminates and substrates are fed into one side of the laminator. Finished laminated material comes out the other side, ready for immediate fabrication.

With Advantage hot melt film adhesive, there is no drying time. Because the adhesive is applied and adhered mechanically, there is no risk of uneven adhesive application caused by human error. Your labor costs will be reduced because you will produce more laminated output, faster, more consistently. You will eliminate waiting for panels to dry, and you won't spend time replacing panels that failed your quality inspection.

By producing more laminated output, faster, and more consistently, you can keep your team busy by accepting more jobs and letting them work on other projects around the shop.

6. Increase Productivity

Fabrication shops worldwide are increasing productivity using HMT's Advantage Laminating System. By replacing time-consuming practices with affordable automation, production output capacities increase. The consistent output further increases productivity by reducing the time and materials devoted to replacing laminated materials that fail QC inspection.

7. Consistent, Even Coverage

HMT's Advantage hot melt adhesive film applies evenly, consistently, in a thin layer with 100% uniform bond coverage. The thin application means less waste, lower adhesive costs, and improved fidelity. Output is very smooth with no pooling, no gapping, no voids. You can't get that consistency with spray adhesives!

8. How It Works

Our adhesive film is activated by exposing it to a brief, intense infrared heat source in HMT Advantage laminating equipment. The heat melts the adhesive film moments before being applied to your laminate and substrate. Your materials are never exposed to the infrared heat which means our adhesive can bond delicate materials such as paper, fabric, plastics without distortion.

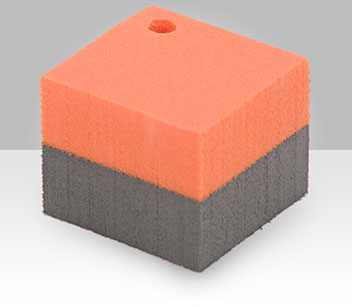

9. Superior Strength

We regularly conduct destructive testing on a variety of laminate surfaces and substrates. In most cases, the bond is stronger than the materials. This picture shows the result of a bond strength test in which HPL was bonded to particleboard and then delaminated.

Notice particleboard fibers still adhere to the back of the laminate. The bond remains intact after the substrate material's integrity failed. Delamination tests show our hot melt adhesive film having 125-150 psi plug-pull strength for particleboard bonded to HPL. Bond strength can vary depending on the materials being bonded.

Notice particleboard fibers still adhere to the back of the laminate. The bond remains intact after the substrate material's integrity failed. Delamination tests show our hot melt adhesive film having 125-150 psi plug-pull strength for particleboard bonded to HPL. Bond strength can vary depending on the materials being bonded.

10. Reliable Quality

Advantage hot melt adhesive film's uniform thickness guarantees consistent area coverage. No voids or hollows under your laminate material. No excess spray or spills in your facility. The perfect amount of adhesive is applied throughout the bonded area, evenly, consistently. No waste, no mess, and no quality defects. The consistent output further increases productivity by reducing the time and materials devoted to replacing laminated materials that fail QC inspection.

11. Bond Flexible Materials (Roll Feed)

With HMT's Advantage Laminating System, you have the option of feeding flexible rolled material for high volume adhesion to substrates. Our roll stock feed attachment allows roll lamination of flexible materials like fabric, paper, melamine, veneers, screen, leather, foil, wall covering, etc.

12. Remains Flexible

Advantage hot melt adhesive film is a smart alternative to white glues and liquid hot melt glues that, when cured, become rigid. Our adhesive remains flexible and is ideal for bonding flexible materials such as fabric, carpet, paper, fiberglass, leather, etc. Our adhesive does not migrate through porous materials, either.

13. Cleaner - No Cleanup Required

HMT's Advantage hot melt adhesive film will be the easiest and most efficient adhesive you'll work with. Unlike other glues, hot melt adhesive film does not produce overspray and is not a liquid. There is no waste on your walls, tables, or floors to clean up. Our adhesive eliminates the need to clean hoses, spray guns, manifolds, nozzles, filters, and flushing the entire system.

14. Healthier

Do you know what's in your adhesive? Solvents, toxins, and VOC's produce invisible air particles that cause reproductive issues, lung damage, neurological damage, headaches, genetic damage causing developmental & cognitive retardation, short-term memory loss, red blood cell damage, nausea, decreases in reaction time, fatigue, and additional medical issues.

HMT Advantage adhesives contain no solvents, no toxins, no VOC's. With HMT's hot melt adhesive, you:

HMT Advantage adhesives contain no solvents, no toxins, no VOC's. With HMT's hot melt adhesive, you:

- don't need respirator masks

- eliminate the need for vapor-proof lighting

- don't need exhaust fans

- get rid of noxious odors

- do not need a spray booth

- create a healthier work environment

- can reduce insurance costs (due to no VOC's)

15. Waterless

Why does it matter if an adhesive contains water? Moisture can impact materials. When adhesive cures (dries), the water in an adhesive must evaporate. For non-permeable materials such as metal, there is nowhere for the water to go when curing. For permeable materials such as paper, water distorts the material by getting into cells, causing wrinkles and warping.

To cure, water-based adhesives require time and space. Simply put, they must sit for an extended period of time until dry. In some cases, dryers are employed to expedite the curing process. Dryers cost money. Running the dryers costs money. Square footage costs money. And, time costs money.

All of those costs are eliminated when using Advantage hot melt adhesive film from HMT Manufacturing. Water-based adhesives require extensive cleanup. Hot melt adhesive film does not. Any water used in the cleanup process of a water-based adhesive is subject to wastewater disposal regulations.

Adhesives are often sold by the pound. Water-based adhesives are often 30%-40% water. Think about what that does to your cost and shipping.

To cure, water-based adhesives require time and space. Simply put, they must sit for an extended period of time until dry. In some cases, dryers are employed to expedite the curing process. Dryers cost money. Running the dryers costs money. Square footage costs money. And, time costs money.

All of those costs are eliminated when using Advantage hot melt adhesive film from HMT Manufacturing. Water-based adhesives require extensive cleanup. Hot melt adhesive film does not. Any water used in the cleanup process of a water-based adhesive is subject to wastewater disposal regulations.

Adhesives are often sold by the pound. Water-based adhesives are often 30%-40% water. Think about what that does to your cost and shipping.

16. Small Footprint

When it comes to equipment, a small footprint is crucial because it minimizes the amount of real estate you need to lease, rent, or purchase. HMT's smallest Advantage laminator is 6'x10′. That means the entire laminating process can occur in 60 square feet (plus an area for panel output, which varies depending on the material you produce). An HMT Advantage laminator uses about 1/3 the space of a spray booth! HMT also builds custom laminating machines of various sizes upon request.

17. Less Waste

If you use spray glues in your fabrication shop, you may be wasting 20% of your glue budget. Why? Because 20% of your glue ends up on the floor, the walls, and the table. The next time you see that mess, imagine how many dollar bills are sticking to your floor, walls, and table.

To make matters worse, imagine the labor cost of cleaning that mess up. There is a solution. Hot melt adhesive film is clean and promotes a waste-free workflow. By applying only the adhesive you need, you will reduce waste to practically zero.

And, you will also enjoy the added benefit of eliminating clean up. During the cleanup of spray glues, you use a significant amount of water and may incur wastewater disposal fees. That adds even more to your cost of ownership for a spray adhesive system.

To make matters worse, imagine the labor cost of cleaning that mess up. There is a solution. Hot melt adhesive film is clean and promotes a waste-free workflow. By applying only the adhesive you need, you will reduce waste to practically zero.

And, you will also enjoy the added benefit of eliminating clean up. During the cleanup of spray glues, you use a significant amount of water and may incur wastewater disposal fees. That adds even more to your cost of ownership for a spray adhesive system.

18. Easy Installation

HMT Advantage lamination equipment is easy to install. Allow a few hours to assemble your new laminator using common tools. With every new laminator, we include a DVD that provides complete assembly instructions and video demonstrations of every assembly step. The DVD includes both English and Spanish versions.

19. Free Technical Support

HMT Manufacturing offers free lifetime technical support during regular business hours for our laminating equipment and adhesives. We provide:

- machine installation guidance

- heat & speed settings

- how to laminate materials you have never laminated before

- tips & techniques

20. Better For Our Planet

Our adhesives have always been free of volatile organic compounds (VOC's) and solvents. 100% of our hot melt products are produced using solar and wind power. Our adhesives use minimal cardboard packaging and that packaging is recyclable. Because our adhesive film is linerless, there are no backing papers or liners to dispose of.

And, unlike messy glues, our adhesives don't require extensive cleaning. That virtually eliminates the need for disposal of toxic wastewater. When you use HMT adhesives in your product, you are using solvent-free, toxin-free, VOC-free material made with renewable energy.

Better for our planet, better for your customers, better for your employees, and better for future generations. HMT Advantage.

And, unlike messy glues, our adhesives don't require extensive cleaning. That virtually eliminates the need for disposal of toxic wastewater. When you use HMT adhesives in your product, you are using solvent-free, toxin-free, VOC-free material made with renewable energy.

Better for our planet, better for your customers, better for your employees, and better for future generations. HMT Advantage.