Company History

HMT Manufacturing began in 1972 and incorporated in 1974. Emil and Burton Bucher started by coating polyester edge banding with hot melt adhesive. Over time, they gained valuable experience and increased their coating operation to include wood, PVC, paper to paper, vinyl to PVC, and vinyl to paper.

The Bucher's had an idea. After months of experimentation, Emil and Burt developed a hot melt adhesive film that was 100% solids, non-toxic, non-shrinking, and offered an almost indefinite shelf life. With new environmental laws curtailing the use of solvent-based adhesives due to toxic VOCs, the development of HMT's new adhesive came at a very opportune time.

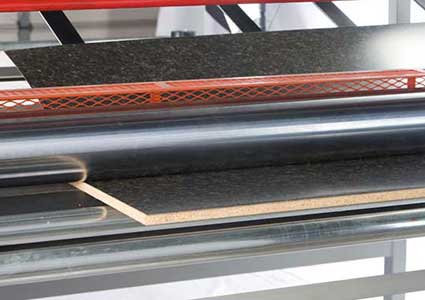

HMT designed and engineered a laminator machine that, using the new hot melt film adhesive, could evenly bond a 4'x8' sheet of particle board with high-pressure laminate in minutes. Their new woodworking machine produced a finished panel that could be fabricated immediately into countertops, cabinets, furniture, etc.

Currently, the laminator can mate many different substrates with numerous laminates. With the development of the roll stock feed attachment, the equipment is no longer limited to sheet stock. Roll goods, such as fabric, wood veneers, melamines, various foils, cork, and a host of other materials can be mated using an HMT Laminator.

As their expertise grew, HMT was able to design custom laminating equipment tailored to specific customer needs. If the current machine would not fit the needed requirements, one would be modified or completely redesigned.

HMT has also developed a line of iron-on adhesives for use in the fabric and arts and crafts industries. Business expanded at a rapid rate, making HMT one of the largest producers of iron-on adhesives in the United States.

Today, HMT Manufacturing continues to improve its laminators, adhesives, and niche products while continuously researching and developing new solutions.