Laminators

No More Waiting for Glue to Dry, No More Clean Up, No More Uneven Adhesive Applications

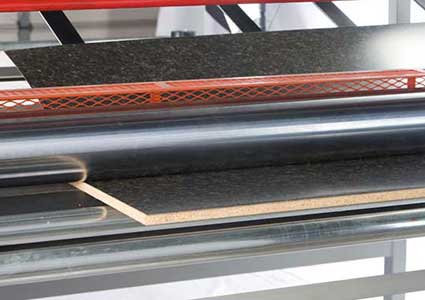

The cost-effective Advantage Laminating System pairs Advantage laminators with Advantage hot melt adhesive film engineered specifically for use together. The Advantage Laminating System adheres a surprising variety of sheet or roll stock laminates using our high performance Advantage hot melt film adhesive. It feeds a substrate and our eco-friendly hot melt adhesive film under infrared heat; laminate is then joined using compression rolls for a finished, ready-to-use panel.

- Laminate unlimited lengths, from 2" to 61" (5 cm to 155 cm) wide

- Laminated output ready for immediate fabrication

- No waiting for drying

- No messy white glue, sprays, or contact cement

- No dripping, no overspray

- No clean up required

- Includes multiple safety features

- Requires little floor space

Easier Height Adjustment

The Elite and Signature include single wheel roller height adjustment with digital height indicator for fast, single-operator adjustments.

American Made With Renewable Energy

Our machines and adhesives are manufactured and assembled in the USA. Our facility is powered by solar panels and a wind turbine.

Easy Installation

Customers can easily install their Advantage Laminating System. Advantage Laminators include a helpful owners manual and web-based step-by-step video instructions. And, free technical support is a phone call away at (800) 433-0730.

Accessories

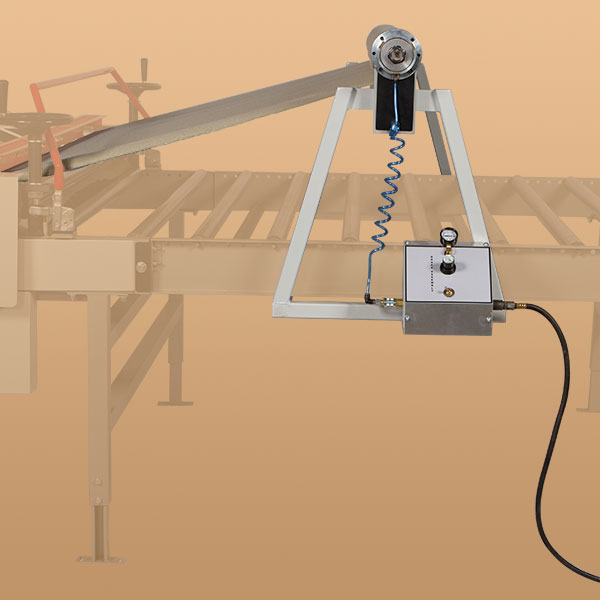

The optional roll stock feed attachment allows users to easily feed rolled stock laminate material (such as melamine, gator ply, fabric, etc). The unit is fitted with 3" (7.6 cm) core chucks and an air clutch which supplies consistent tension across the pay out bar.

The included hot knife adhesive cutter is a heated arm that reaches across the width of your laminator. Operators won't need to bend over the panel to cut adhesive. Instead, a quick flick of the wrist pushes the arm through the adhesive, making a fast and clean cut.

These conveyors extend the length of the machine, making it easier to handle full size panels. Your laminating machines can be fitted with additional conveyor sections as needed. Conveyor sections are available in 5’ (152 cm) lengths and can be ordered with or without legs.

Articles Selected For You

Seeing is believing. Let us run samples of your material through the Advantage Laminating System and send them to you:

- INSPECT the bond quality

- FEEL the finished product

- SEE for yourself why HMT's Advantage Laminating System could be the smartest investment you make

Luan bonded to Polyethylene Honeycomb

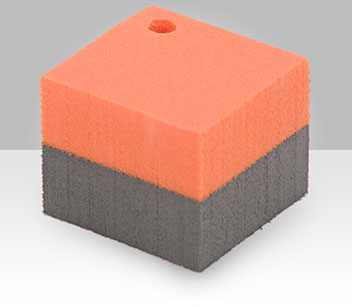

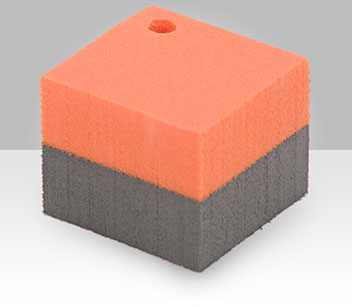

Scrub Pad bonded to Sponge

Burlap Fabric bonded to Cardboard Honeycomb

EVA Foam bonded to EVA Foam

Carpet bonded to Marine Grade Plywood

Pool Table Felt bonded to High Density Fiberboard

Fiberglass Scrim bonded to Ceramic Foam

Acoustic Insulation Felt bonded to Aluminum Foil

Vertical Grade Laminate bonded to Particleboard

Pinboard Fabric bonded to Wheatboard bonded to Cork

Fabric bonded to Rubber bonded to PVC Board