Reduced labor cost = higher profit and faster fabrication. But how does a fabricator reduce labor cost without sacrificing quality or laying off friends in the shop? Answer: automation and advanced materials.

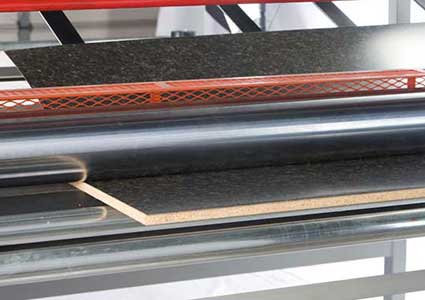

HMT’s Advantage laminator equipment applies consistent hot melt adhesive on a semi-automatic basis. Compared to manual, liquid hot melt glues, HMT adhesives reduce labor costs by up to 50% while offering 10 times more output. Laminates and substrates are fed into one side of the laminator. Finished laminated material comes out the other side, ready for immediate fabrication. With Advantage hot melt film adhesive, there is no drying time. Because the adhesive is applied and adhered mechanically, there is no risk of uneven adhesive application caused by human error.

Your labor costs will be reduced because you will produce more laminated output, faster, more consistently. You will eliminate waiting for panels to dry, and you won’t spend time replacing panels that failed your quality inspection. By producing more laminated output, faster, and more consistently, you can keep your team busy by accepting more jobs and letting them work on other projects around the shop.

You probably have questions. Contact us today and we will be happy to help!