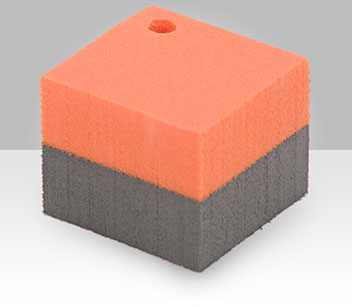

HMT’s Advantage Laminating System provides fast, consistent lamination of a substrate and a laminate. Laminates can be practically ANY material. Here’s how it works:

- Turn on the laminator. Adjust the heat, compression, and speed of the rollers based on the material to be adhered.

- Place your substrate material on the infeed rollers.

- Pull hot melt film adhesive over the substrate and trim to length using the optional hot knife adhesive cutter or a shop knife.

- FOR FLAT LAMINATES: Place the laminate on the upper rack.

- FOR FLEXIBLE LAMINATES: Place a roll of laminate material on the optional roll stock feed attachment.

- Slide the substrate (with adhesive film on it) toward the heating element. Stand back and let the laminator take over.

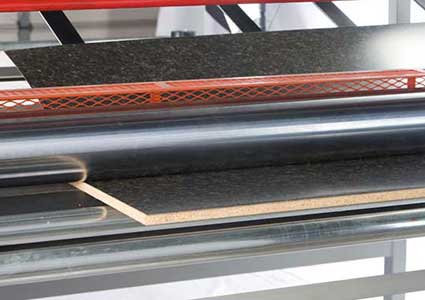

- The laminator will roll the adhesive film and substrate past the heating element to activate the adhesive.

- As the substrate and activated adhesive proceed through the machine and away from the heating element, your laminate material will automatically mate with the substrate. Compression (based on user settings) is applied to secure the laminate to the substrate.

- Laminated material comes out the outfeed side, ready for immediate fabrication.

For a more in-depth understanding, watch this video: