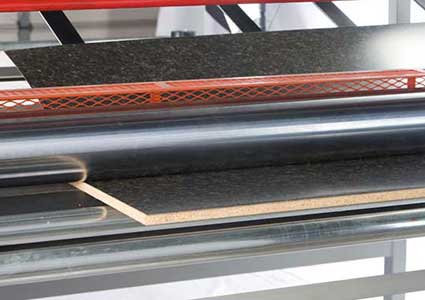

Fabrication shops worldwide are increasing productivity using HMT’s Advantage Laminating System. By replacing time consuming practices with affordable automation, production output capacities increase. The consistent output further increases productivity by reducing the time and materials devoted to replacing laminated materials that fail QC inspection.

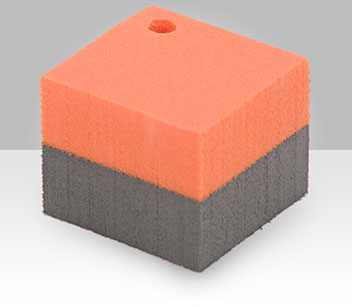

HMT’s Advantage Laminating System uses unique hot melt adhesive film to laminate nearly any material to practically any substrate. The System is currently used to glue particleboard, high pressure laminate, wood veneers, linoleum, leather, vinyl, cork, felt, aluminum foil, textured wall covering, carpet, screen, fabric, metal, hook-and-loop, plastic, sponge, foam, aluminum, rubber, insulation, and much more.

To increase productivity in your facility, learn more about Advantage Laminating Equipment and Adhesive. Contact us today with any questions and to request a sample of your material bonded with our adhesive using our machines.