Are you still using spray adhesives, white glues, or contact adhesive to bond high pressure laminate (HPL) to a substrate such as MDF, plywood, particleboard, or practically any material? There is a better way.

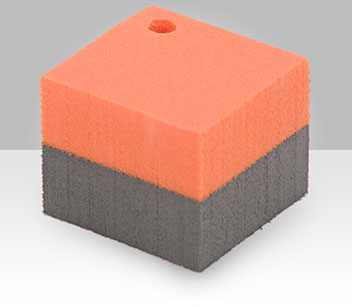

Hot melt adhesive film is easy to work with, provides an unbeatable consistent bond, dramatically speeds up production, is healthier to work with, easier to clean, uses less floorspace, and offers another half dozen benefits.

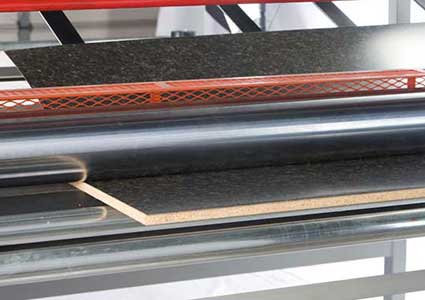

Woodworkers, cabinet makers, furniture manufacturers, door companies, etc have used HMT’s Advantage hot melt film adhesive for more than four decades to bond HPL laminate. Why? Because our adhesive’s unique structure — solid, non-shrinking, non-toxic glue in a solid, thin, fabric-like format — guarantees consistent adhesive coverage. No voids or hollows under your high pressure laminate. No excess spray or spills in your facility. And, finished panels are ready for immediate fabrication. Rather than waiting for glue to cure/dry, bonded materials exit our lamination machinery ready to use. You can cut, drill, route, and handle them. Our customers can offer faster turnaround time while reducing the amount of real estate needed (no more curing means no more finding space to let panels cure!).

Seeing is believing. May we provide you with a free sample? We can run your HPL laminate and substrate through our laminating machinery, using Advantage hot melt adhesive, and ship it to you so you may inspect the quality with your own eyes and fingers. Or, schedule a visit to our Illinois facility (located between Chicago and Milwaukee).